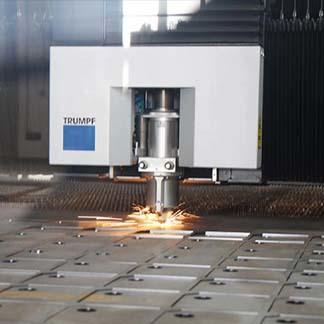

In Order To Meet The High Demand Of Product Performance And Individuation, With perfect production and processing equipment, Joylive Strictly Follow International QC Management In Practicing “6S” Field-Management And Lean Production Management To Make Sure Producing High-Grade, Precision And Advanced Elevators For Every User.

Web Menu

Product Search

Exit Menu

CNAS Approved Laboratory

Joylive’s Laboratory Has Been Approved By CNAS And Has Become A National Laboratory. It Is A High Recognition Of The Inspection And Testing Level And Quality Management Of The Company's Elevator Products, Indicating That The Company's Elevator Research And Development, Quality Control Testing Accuracy, Effectiveness And Scientificity Have Reached International Level.

Elevator Testing Tower

Joylive For Its Worldwide Elevator Business, Manufactures More Than 20,000 Units Of Elevators And Escalators Annually And Is Also Dedicated To Developing New Products To Introduce To Global Market. In Order To Develop Elevators, The Performance And Quality Need To Be Tested Using Actual Elevators, Which Had Been Accommodated By The Testing Towers. The Testing Tower Is 118m Height (6 Test Shafts), Max. Test Speed Is 8m/S.

Growing toward the global...

We are always working diligently to create a better future for our world with innovative and Eco-friendly vertical transporation management systems.

-

No. 322, Maoxu Road, Bacheng Town, Kunshan-Suzhou City, Jiangsu Province, China

-

+86 512 5780 6555

+86 156 1872 5928

-

Copyright © 2002 - 2024 Joylive Elevator Co., Ltd. All Rights Reserved

English

English русский

русский Español

Español